Hey everyone,

I thought it's about time I explain why the posts have fallen completely off. As you know, I had and still have a large list of things to accomplish here at "the ranch". In addition to that, because of my love for energy efficiency and the environment, I'm part of a group that is in the process of starting a non-profit education network. My job on the board is Secretary and a good portion of my free time is being spent disseminating information to the board and our members as we grow our network. By the way, the name of the network is the Mid Columbia Energy and Environmental Network (MCEEN). I'm thinking this endeavor is going to take the majority of my energies for the next several months, at least. We have a very affluent team to get the organization started. We plan on the network to be a "go to" place for information on all energy and environmental education, both residential and non-residential. Our event planner, Tracy Roberts who owns Tri-City Events, is helping put together a website, forum and blog for MCEEN. When it is up and running, be sure to check it out. It should prove to be a great resource for information.

Nothing is Absolute

19 hours ago

Early people of this land had a thing for doors! This is the "during" shot of the kitchen. There are actually four...FOUR! doors in the kitchen. The left door was taken out (it goes to the foyer) and the right door leads to the "root cellar", which was originally where the coal was deposited.

Early people of this land had a thing for doors! This is the "during" shot of the kitchen. There are actually four...FOUR! doors in the kitchen. The left door was taken out (it goes to the foyer) and the right door leads to the "root cellar", which was originally where the coal was deposited. Here is the before of the kitchen. Again, notice the acoustic tile..and what a beautiful floor! And ew, it was nasty, gross, dirty!

Here is the before of the kitchen. Again, notice the acoustic tile..and what a beautiful floor! And ew, it was nasty, gross, dirty!  The west side of the house shortly after we'd bought it. Notice the window by the tree in the shed addition. Yes, that's plywood. They boarded it up and put a shower stall over it.

The west side of the house shortly after we'd bought it. Notice the window by the tree in the shed addition. Yes, that's plywood. They boarded it up and put a shower stall over it. That's right get mad at the wall..not at me! I had said..."oh, a little paint and it'll be sweet!" We first tried to preserve the plaster walls and redo the woodwork in place...

That's right get mad at the wall..not at me! I had said..."oh, a little paint and it'll be sweet!" We first tried to preserve the plaster walls and redo the woodwork in place... OK..really out of order..pay no attention to this yet..(Sylvia filling in two of the raised beds I built her) The other garden you'll see came first.

OK..really out of order..pay no attention to this yet..(Sylvia filling in two of the raised beds I built her) The other garden you'll see came first.

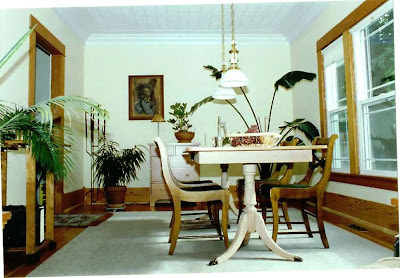

The dining room..a basic mirror image of the living room. I miss the wood trim and the nine inch mop boards.

The dining room..a basic mirror image of the living room. I miss the wood trim and the nine inch mop boards. This bathroom was GGGGRRRROSS!!! The old couple that lived here (son of the builder and his wife) hadn't been upstairs in about five years. Evidently before he'd moved downstairs, he'd lost his ability to aim...

This bathroom was GGGGRRRROSS!!! The old couple that lived here (son of the builder and his wife) hadn't been upstairs in about five years. Evidently before he'd moved downstairs, he'd lost his ability to aim... Again, out of order. The kitchen after. You are looking directly at where the door to the foyer used to be. The floors were not salvagable (spell check says that's not a "real" word") Well...screw spell check. Notice the soffit is directly in line with the edge of the cabinets. Things go like this in our house..Sylvia: "I want the box on top to line up with the bottom." Vic: "But, that's not hows it's done." Sylvia: "Well, can you do it?"Vic (begrudgingly):"I don't know, I'll try." (See that's the reason she keeps me around, I have no idea that I really can't do stuff!!)

Again, out of order. The kitchen after. You are looking directly at where the door to the foyer used to be. The floors were not salvagable (spell check says that's not a "real" word") Well...screw spell check. Notice the soffit is directly in line with the edge of the cabinets. Things go like this in our house..Sylvia: "I want the box on top to line up with the bottom." Vic: "But, that's not hows it's done." Sylvia: "Well, can you do it?"Vic (begrudgingly):"I don't know, I'll try." (See that's the reason she keeps me around, I have no idea that I really can't do stuff!!) Ta Da..go back to the nasty picture of the bathroom. .....Much better...no more nasty urine smell either....BONUS!

Ta Da..go back to the nasty picture of the bathroom. .....Much better...no more nasty urine smell either....BONUS! Well Kari and Nancy, I hope you've enjoyed this trip down memory lane with me. Designs by Vic and Sylvia...mostly Sylvia...it's really her house...even in the new one.

Well Kari and Nancy, I hope you've enjoyed this trip down memory lane with me. Designs by Vic and Sylvia...mostly Sylvia...it's really her house...even in the new one.